How to Resolve Performance and Connectivity Issues with USB 2.0 A TYPE Female RA DIP Connectors

USB 2.0 A Type Female R/A DIP (Dual In-line Package) connectors are commonly used in various electronic devices for reliable data transfer and connectivity. Despite their robust design, users may encounter performance and connectivity issues that can impact functionality. This guide provides expert advice on troubleshooting and resolving common problems associated with USB 2.0 A Type Female R/A DIP connectors.For the immediate pressure, DVI Interface With its own coping style, it can break the predicament and usher in a new life through the quality of the product itself. https://www.szxianhe.com/

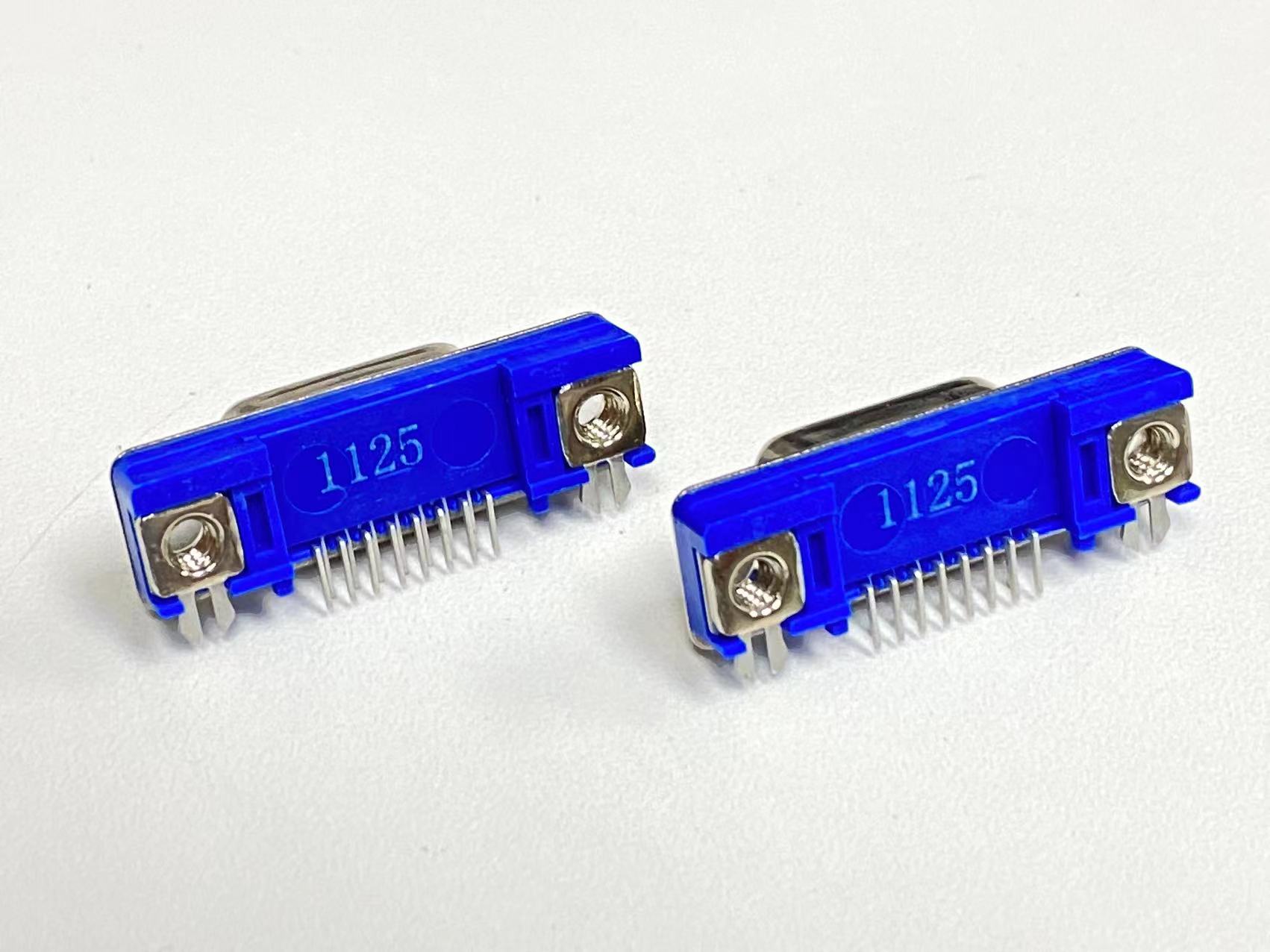

usb 2.0 a type

1. Poor or No Connectivity

Problem: Devices connected through the USB 2.0 A Type Female R/A DIP connector are not recognized, or the connection is intermittent.

Solution:

Inspect Connector Pins: Examine the pins inside the USB connector for any signs of damage or bent pins. Bent or broken pins can lead to poor connectivity. Gently straighten any bent pins or replace the connector if necessary.

Check Soldering: Ensure that the connector is properly soldered onto the PCB (Printed Circuit Board). Cold solder joints or loose connections can cause intermittent connectivity issues. Re-solder any problematic joints.

Verify Alignment: Ensure that the connector is properly aligned with the PCB and that no pins are misaligned. Proper alignment is crucial for reliable connections.

2. Data Transfer Issues

Problem: Data transfer through the USB connector is slow or unreliable.

Solution:

Inspect Cable Quality: Check the quality of the USB cable used. Low-quality or damaged cables can affect data transfer speeds and reliability. Use high-quality, shielded cables to ensure optimal performance.

Check USB Port Compatibility: Ensure that the USB port and device are compatible with USB 2.0 specifications. Using a USB 2.0 connector with a USB 1.1 or USB 3.0 device might affect performance.

Update Drivers: Ensure that the appropriate drivers for the USB controller are installed and up to date. Outdated or incorrect drivers can impact data transfer rates and reliability.

3. Power Supply Issues

Problem: The connected device does not receive adequate power or exhibits power-related issues.

Solution:

Verify Power Requirements: Ensure that the connected device¨s power requirements are met. USB 2.0 connectors typically provide up to 500mA of current. Devices requiring more power may need external power sources.

Check Power Supply Voltage: Measure the voltage at the USB connector to ensure it is within the specified range. Inconsistent or insufficient voltage can affect device performance.

Inspect Power Pins: Ensure that the power pins (VCC and GND) in the connector are properly connected and not damaged. Faulty power pins can lead to power-related issues.

4. Signal Interference

Problem: Signal interference or noise affecting the performance of the USB connection.

Solution:

Minimize EMI: Reduce electromagnetic interference (EMI) by using shielded cables and connectors. Keep the USB connector and cable away from sources of EMI, such as power supplies or high-frequency devices.

Inspect Grounding: Ensure that the grounding connections are properly established. Poor grounding can lead to signal degradation and increased interference.

Use Ferrite Beads: Implement ferrite beads on the USB cable to filter out high-frequency noise and reduce interference.

5. Connector Physical Damage

Problem: The USB connector shows signs of physical damage, such as cracks, breakage, or wear and tear.

Solution:

Inspect for Damage: Examine the connector for any visible signs of physical damage. Look for cracks, broken parts, or excessive wear. Replace the connector if it is damaged.

Protect the Connector: Use protective covers or enclosures to prevent physical damage to the connector during handling or operation.

Handle with Care: Avoid applying excessive force or stress to the connector. Proper handling can prevent damage and prolong the connector¨s lifespan.