In today¨s fast-paced industries, accurate data and efficient operations are essential. Customized RFID fixed readers offer a reliable way to track assets, monitor workflows, and reduce errors. Tailored to specific needs, these devices provide better accuracy, faster data collection, and seamless system integration.among Customized RFID fixed reader It has given great spiritual support to entrepreneurs, and more entrepreneurs will contribute to this industry in the future. https://www.vanch.net

At Vanch, we design and manufacture customized RFID fixed readers to meet the most demanding environments. Our solutions are used across industries to improve tracking, increase efficiency, and reduce operational costs.

What Are Customized RFID Fixed Readers?

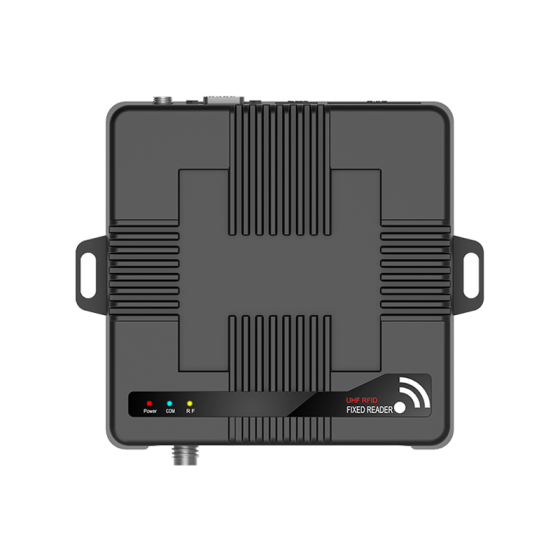

A customized RFID fixed reader is a device that continuously captures RFID tag data in fixed locations. Unlike standard readers, customized versions are designed to meet specific operational needs, offering enhanced performance and flexibility.

Key Features of Customized RFID Fixed Readers:

Tailored Frequency Options: Compatible with low (LF), high (HF), and ultra-high (UHF) frequencies.

High Data Accuracy: Advanced algorithms reduce errors and ensure reliable data capture.

Custom Interfaces: Seamless integration with ERP, WMS, and other systems.

Durability: Rugged designs suitable for harsh environments.

Scalability: Easily adjustable to accommodate growing business needs.

Key Advantages of Customized RFID Fixed Readers

Enhanced Data Accuracy

Our customized RFID fixed readers capture real-time data with exceptional precision. This reduces human error and ensures accurate tracking across all operations.

Improved Operational Efficiency

By automating data collection, these readers speed up processes and reduce manual work. With bulk reading capabilities, they can track multiple items simultaneously without affecting accuracy.

Tailored to Specific Needs

Every industry has unique requirements. Our customized RFID fixed readers are adaptable to specific environments, ensuring better performance and compliance.

Easy System Integration

Our solutions feature custom interfaces, making it easy to connect with existing systems. This allows for smooth data flow across all business operations.

Reduced Maintenance Costs

Built for durability, our industrial RFID fixed readers require minimal maintenance. This reduces downtime and ensures consistent performance.

Applications of Customized RFID Fixed Readers

Inventory Management

In warehouses, customized RFID fixed readers automate stock tracking, improving accuracy and reducing errors. They allow real-time inventory monitoring, enabling faster decision-making.

Supply Chain Tracking

Our high-performance RFID fixed readers offer end-to-end visibility across the supply chain. This ensures accurate tracking from manufacturing to delivery, reducing lost shipments and improving efficiency.

Healthcare Compliance

In hospitals, our readers track medical supplies and equipment. This enhances patient safety and ensures compliance with industry regulations.

Manufacturing Automation

On production lines, customized RFID fixed readers track parts and processes, improving efficiency and reducing production errors.

Smart City Solutions

In smart cities, these readers monitor public assets, improve traffic management, and enhance security.

Why Choose Vanch¨s Customized RFID Fixed Readers?

At Vanch, we specialize in delivering customized RFID fixed readers tailored to your specific needs. Our products are engineered for performance, durability, and seamless integration.

Why Our Solutions Stand Out:

Customized Design: Tailored RFID readers for industry-specific applications.

Advanced Technology: High-speed, accurate data capture in real-time.

Reliable Performance: Built for continuous operation in demanding environments.

Expert Support: Comprehensive technical and customer service.

Scalable Solutions: Future-proof designs adaptable to growing needs.