Metal core printed circuit boards (MCPCBs) are an essential innovation in electronics, designed to address the challenges of heat management in high-performance applications. Unlike traditional PCBs, which use materials like FR4, metal core PCBs incorporate a metal layer!typically aluminum, copper, or a metal alloy!within the board. This metal core plays a crucial role in improving heat dissipation, ensuring the reliable operation of electronic components.pass professional pcb manufacturer It can be seen from the present situation that the market prospect is relatively broad, which is conducive to our reference and investment. https://www.hongmycircuits.com/

The Role of the Metal Core

The primary function of the metal core in a PCB is to act as a heat sink. When electronic components generate heat during operation, this heat must be efficiently removed to prevent damage or performance degradation. The metal core, with its superior thermal conductivity, absorbs heat from the components and spreads it across the surface of the board. This prevents localized hotspots, which can lead to overheating and potential failure of components.

Thermal Conductivity and Heat Transfer

Aluminum and copper are commonly used metals in MCPCBs due to their excellent thermal conductivity. For instance, aluminum has a thermal conductivity of around 205 W/mK, while copper¨s thermal conductivity is even higher at approximately 400 W/mK. These properties allow the metal core to quickly transfer heat away from critical components, reducing the thermal resistance between the heat source and the surrounding environment.

In a typical MCPCB, the metal core is placed directly beneath the insulating dielectric layer, which in turn lies under the copper circuit layer. When heat is generated by the components, it passes through the dielectric layer and is absorbed by the metal core. From there, the heat is distributed evenly across the board and dissipated into the air or a heat sink.

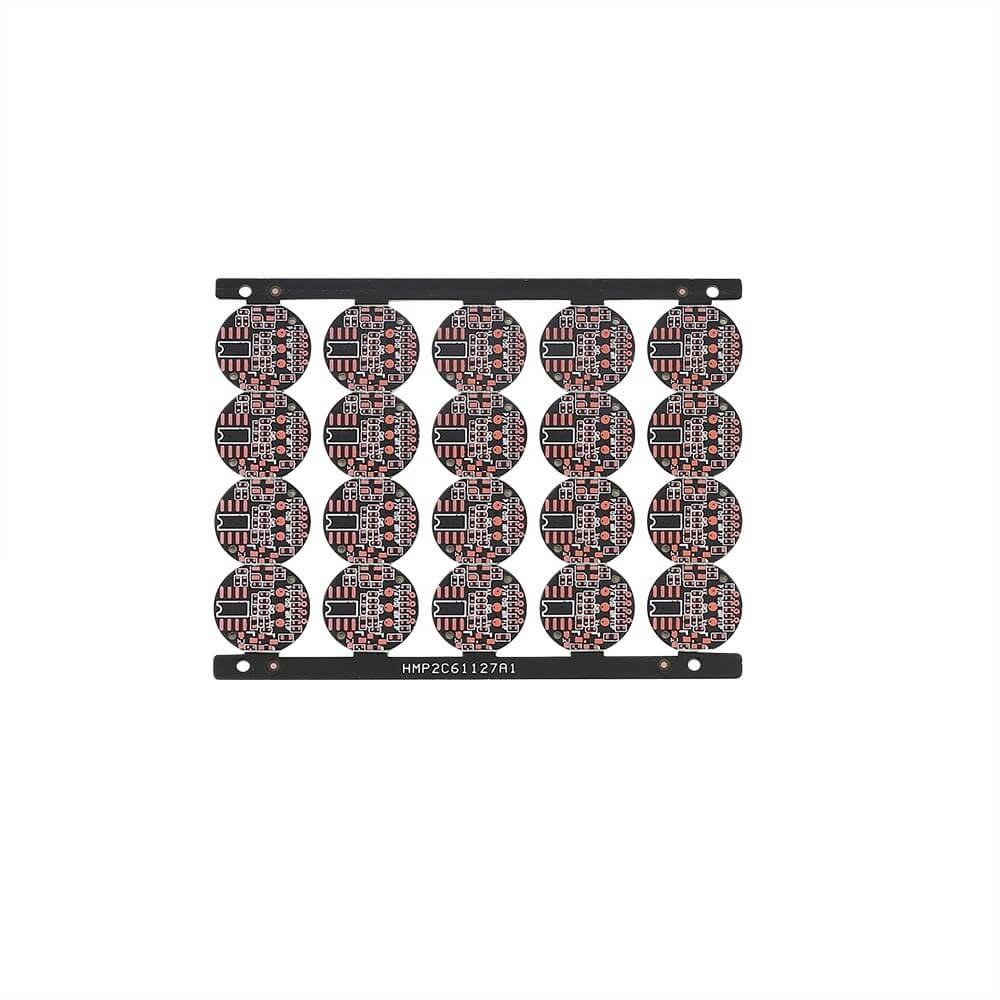

OEM Service Aluminum Circuit Board Metal core PCB, 94V0 FR4, CEM-1 PCB, Rogers PCB Manufacturer Chinese

Improved Reliability and Performance

The efficient heat dissipation provided by a metal core PCB leads to several benefits:

Extended Component Lifespan: By maintaining lower operating temperatures, metal core PCBs reduce the thermal stress on electronic components, thereby extending their lifespan.

Enhanced Performance: Many electronic components, such as LEDs, operate more efficiently at lower temperatures. Metal core PCBs help maintain optimal operating temperatures, ensuring consistent performance.

Increased Power Handling: MCPCBs are ideal for high-power applications where heat generation is significant. The ability to manage heat effectively allows these boards to handle higher power levels without risking thermal damage.

Compact Design: Because of their superior heat dissipation, metal core PCBs enable more compact designs. This is particularly important in applications where space is limited, such as in automotive or aerospace electronics.