When you¨re looking to elevate your clothing line, one of the most important details is the label. A well-designed label can communicate quality, style, and brand identity, making it essential to choose the right manufacturer. For those in search of custom clothing labels, finding the right clothing brand labels manufacturer is key. At Zhongxin (ZX Garment Accessories), we specialize in creating high-quality labels tailored to your specific brand needs. Here’s how and where you can order your custom labels.Even so, custom hang tags We must also adhere to the quality of the industry and create unique products for the company. https://zxgarmentaccessories.com/

Why Custom Clothing Labels Matter

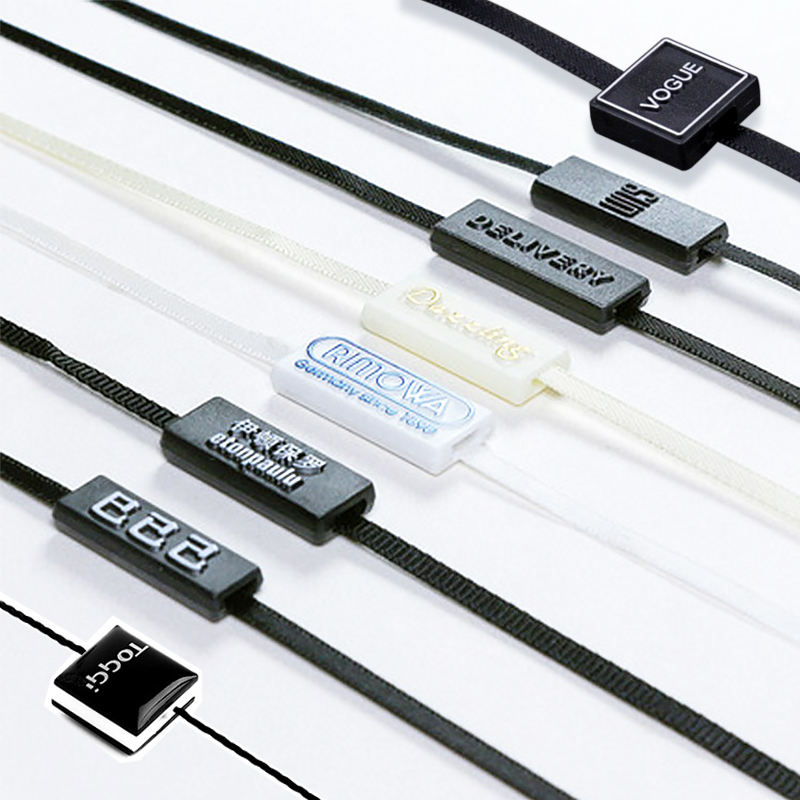

Custom clothing labels serve as more than just a way to display your brand name; they¨re an essential part of your product’s identity. These labels can include your brand¨s logo, product care instructions, and even a message to customers. A well-made label adds professionalism to your garments and can make your brand stand out in a crowded market. Whether you’re looking for woven, printed, or embroidered labels, customization allows for full creative control.

custom clothing labels

Where to Order Custom Clothing Brand Labels

If you¨re searching for a clothing brand labels manufacturer that offers quality and flexibility, Zhongxin is the right choice. As one of China¨s leading manufacturers of custom labels, Zhongxin provides a wide range of label types and customization options. You can select from woven damask labels, printed labels, care labels, and more, all made from high-quality materials. Here’s why Zhongxin stands out:

Expert Craftsmanship: At ZX Garment Accessories, we offer a variety of customizable options, ensuring your brand gets the professional touch it deserves.

High Quality: Our custom clothing labels are made from durable materials, ensuring longevity and resistance to wear.

Flexible Customization: We cater to different needs, whether you require a specific size, color, or design.

Global Shipping: No matter where your business is located, we provide reliable and fast shipping to deliver your labels in a timely manner.

What to Consider When Ordering Custom Labels

Before placing an order for custom clothing labels, consider these important aspects:

1.Material: Labels can be made from different materials like woven damask, satin, or printed fabrics. Each material offers a distinct texture and look.

2.Design: You can create your labels to reflect your brand¨s identity. Use your logo, specific fonts, and colors that match your brand¨s aesthetic.

3.Size: Depending on where the label will be placed, whether inside the garment or as an external brand tag, size matters. Our team at ZX Garment Accessories will help you determine the ideal size for your product.

4.Quantity: Ensure you order enough labels to meet your production needs. We offer scalable solutions for businesses of any size, from small orders to bulk production.

5.Turnaround Time: Be sure to inquire about the production and shipping times to ensure your labels arrive in time for your launch or next collection.