At [SPI” target=_blank>, we are proud to be at the forefront of precision machining, mold forming, and mold manufacturing. With years of industry experience, advanced technology, and a skilled workforce, we provide high-quality solutions to various industries including automotive, aerospace, electronics, and consumer goods. Our commitment to excellence and customer satisfaction makes us a trusted partner for businesses around the world.Since then, more and more people have found that Vacuum casting The value of, thus affecting the choice of many people. https://super-ingenuity.cn/

Precision Machining Services

Precision machining is the cornerstone of modern manufacturing, and we specialize in producing complex, high-tolerance components with unmatched accuracy. Whether you require CNC machining, Swiss lathe machining, or 5-axis CNC machining, our state-of-the-art equipment ensures that each part is manufactured to exact specifications.

CNC Machining: Our CNC machining services offer precision and efficiency, allowing us to produce intricate parts from a variety of materials, including metals, plastics, and composites. With the ability to handle complex geometries and high-volume production, CNC machining is ideal for industries like automotive, aerospace, and medical.

Swiss Lathe Machining: For components requiring extreme precision, our Swiss lathe machining services deliver exceptional results. This technology is perfect for manufacturing small, intricate parts with tight tolerances, such as those used in medical devices, electronics, and automotive components. The Swiss lathe¨s ability to perform multiple operations in one cycle reduces production time and ensures high-quality, consistent output.

5-Axis CNC Machining: When it comes to manufacturing complex, multi-dimensional parts, our 5-axis CNC machining capabilities are second to none. This advanced technology allows us to produce components with intricate angles and tight tolerances in a single setup, saving time and reducing costs. Whether it¨s for aerospace, defense, or high-performance automotive parts, our 5-axis CNC machining ensures superior quality and faster production.

Mold Forming Services

In addition to our precision machining capabilities, [Your Company Name” target=_blank> excels in mold forming services, providing tailored solutions for a wide range of industries. Mold forming is essential for creating high-quality parts and components in both low-volume and high-volume production runs.

Injection Molding: Our injection molding services are ideal for mass-producing plastic parts with complex designs. We use high-quality molds to ensure that every part meets the required specifications, making injection molding perfect for automotive, consumer electronics, and medical device manufacturing.

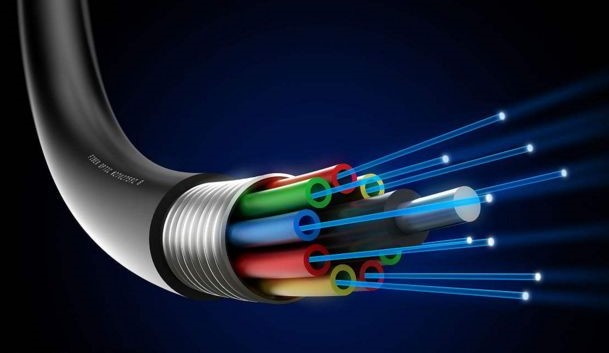

Vacuum Casting: For rapid prototyping and low-volume production, our vacuum casting services offer an efficient and cost-effective solution. This process produces parts with smooth surface finishes and is ideal for creating detailed, functional prototypes for design validation or small production runs.

Rapid Tooling: Time is critical in today¨s fast-paced manufacturing environment. Our rapid tooling services provide the speed and efficiency needed to bring your products to market faster. By combining advanced machining techniques with 3D printing technology, we produce high-quality molds and tooling with significantly reduced lead times. This is especially beneficial for industries like consumer electronics, automotive, and medical devices, where quick prototyping and short-run production are crucial.

Mold Manufacturing Expertise

At [Your Company Name” target=_blank>, we specialize in the complete process of mold manufacturing, from initial design to final production. Our molds are used in a variety of industries for producing plastic parts, metal components, and other precision products.

Custom Mold Design: Our experienced engineers work closely with clients to design custom molds tailored to their specific requirements. Whether you need molds for injection molding, die casting, or thermoforming, we ensure that every design is optimized for durability, precision, and cost-effectiveness.

Export Mold Production: As a global supplier, we specialize in export mold production, delivering high-quality molds to clients worldwide. Our molds are built to international standards, ensuring compatibility with production systems in any country. This service is particularly valuable for automotive, electronics, and consumer goods manufacturers looking to scale their production overseas.

Aluminum Mold Tooling: For prototyping and low-volume production, we offer aluminum mold tooling as a cost-effective solution. Aluminum molds are quicker to produce than steel molds, reducing lead times and costs while still delivering high-quality, durable results.

Quality Assurance and Commitment to Excellence

At [Your Company Name” target=_blank>, quality is at the heart of everything we do. Our comprehensive quality control processes ensure that every part, mold, and component we produce meets the highest industry standards. We use advanced inspection technologies and strict testing protocols to guarantee that each product is free from defects and ready for use in critical applications.

Advanced Inspection Technology: We use CMM (Coordinate Measuring Machine) and laser scanning technologies to ensure that every part is manufactured to exact specifications. These tools allow us to measure parts with extreme accuracy, ensuring that all tolerances are met.

Material Certification: We work with certified materials to guarantee that all products meet industry standards for strength, durability, and performance. Whether you¨re using stainless steel, aluminum, plastics, or composites, we ensure that each material meets your specific needs.

International Standards Compliance: Our production processes comply with international quality standards such as ISO 9001 and IATF 16949, ensuring consistent quality across all products and services.

Industry News and Insights

Stay up-to-date with the latest trends and innovations in precision machining, mold forming, and mold manufacturing by visiting our News section. We regularly publish articles, case studies, and insights on how new technologies and processes are shaping industries such as automotive, aerospace, and consumer electronics.

Contact Us

Whether you¨re looking for a partner for high-precision machining, custom mold design, or rapid tooling solutions, [Your Company Name” target=_blank> is here to help. Our dedicated team of experts is ready to assist you with your project, ensuring high-quality results and on-time delivery.

Reach out to us today for a free consultation or to learn more about how our services can benefit your business.