However, in other words, we should know more about it. point of sale terminal The law of development has brought new vitality to the whole industry and revitalized the market. https://www.posodm.com

In the competitive world of POS hardware manufacturers, ensuring quality control is paramount for maintaining a strong reputation and customer trust. A POS machine factory employs several rigorous processes and standards to guarantee the reliability and performance of point of sale machines. Here’s a detailed look into how these factories ensure quality control:

1. Stringent Supplier Selection

POS hardware manufacturers begin by carefully selecting suppliers for components. Only suppliers who meet strict quality standards and provide high-grade materials are chosen. This initial step is crucial because the quality of the components directly affects the overall performance of the POS machines.

2. Incoming Material Inspection

Upon receiving components, a POS machine factory conducts thorough inspections to verify their quality. This includes checking for defects, ensuring they meet the specified requirements, and conducting random sampling tests. Any subpar materials are rejected to prevent compromising the quality of the final product.

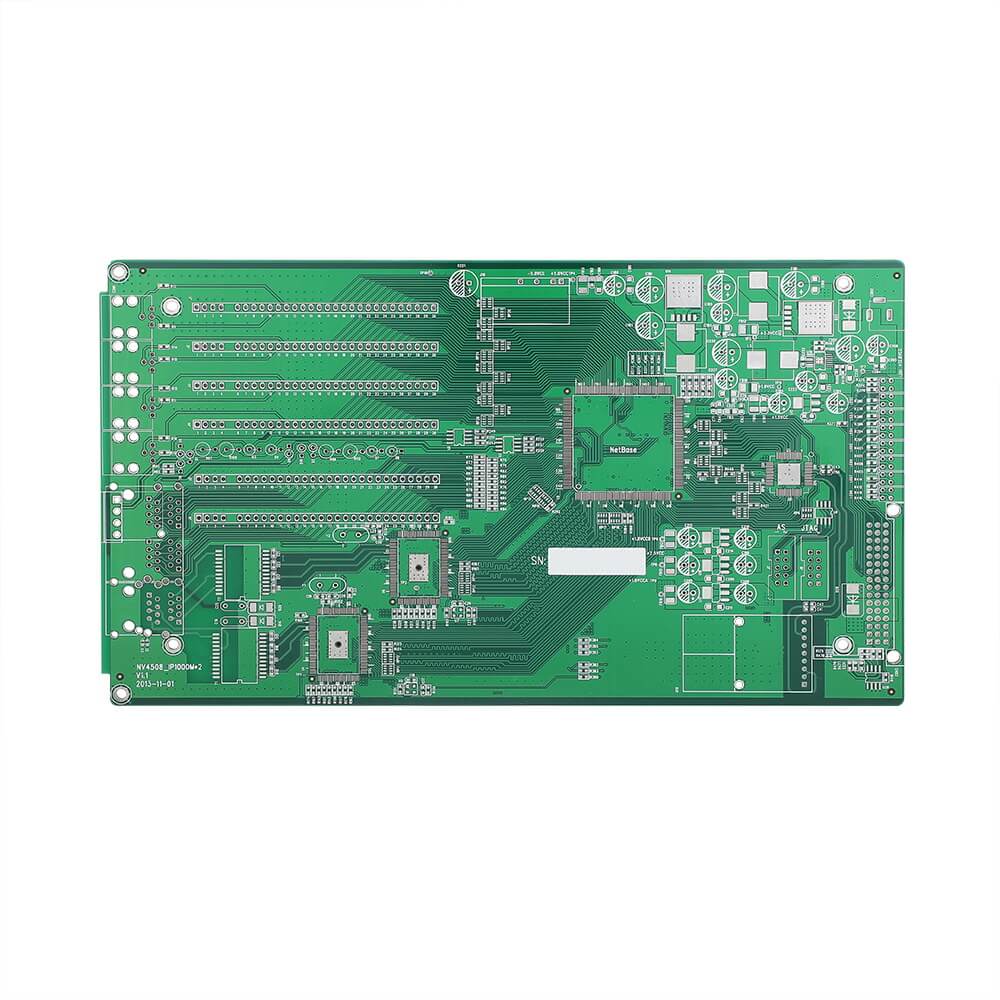

3. Advanced Manufacturing Processes

Manufacturing processes in a POS machine factory are highly automated and utilize state-of-the-art technology. This ensures precision and consistency in the production of POS machines. Automation also reduces human error, which can lead to defects and inconsistencies.

point of sale all in one pos system.jpg

4. In-Process Quality Checks

Quality control doesn¨t end with the initial inspection; it continues throughout the manufacturing process. POS machine factories implement in-process quality checks at various stages of production. These checks include visual inspections, functional tests, and performance evaluations to identify and rectify any issues immediately.

5. Comprehensive Testing

Once the POS machines are assembled, they undergo comprehensive testing. This includes:

Functional Testing: Ensuring all features and functionalities work as intended.

Stress Testing: Subjecting the machines to extreme conditions to assess their durability and reliability.

Compatibility Testing: Verifying that the machines work seamlessly with various software and peripheral devices.

6. Quality Assurance Teams

A dedicated quality assurance (QA) team in a POS machine factory plays a critical role in maintaining high standards. This team comprises experts who continuously monitor production processes, conduct audits, and implement quality improvement initiatives. They also ensure compliance with industry standards and regulations.

pos hardware manufacturers.jpg

pos hardware manufacturer.jpg

7. Feedback and Continuous Improvement

POS hardware manufacturers actively seek feedback from customers and end-users. This feedback is invaluable for identifying areas of improvement. Factories analyze this data to make continuous enhancements to their products and processes, ensuring that the POS machines they produce remain top-tier.

8. Final Quality Inspection

Before shipment, each POS machine undergoes a final quality inspection. This is a thorough check to ensure that the product meets all quality standards and specifications. Only machines that pass this inspection are approved for distribution.

9. Certifications and Standards Compliance

Reputable POS machine factories adhere to international quality standards such as ISO 9001. These certifications demonstrate a commitment to quality management systems and continuous improvement. Compliance with these standards ensures that the factory maintains a high level of quality in its manufacturing processes.

The commitment to quality control in a POS machine factory is evident in every step of the production process, from supplier selection to final inspection. By implementing stringent quality checks and leveraging advanced technology, POS hardware manufacturers ensure that their point of sale machines are reliable, durable, and meet the highest industry standards. This meticulous attention to quality not only enhances the performance of POS machines but also reinforces the trust and satisfaction of customers worldwide.