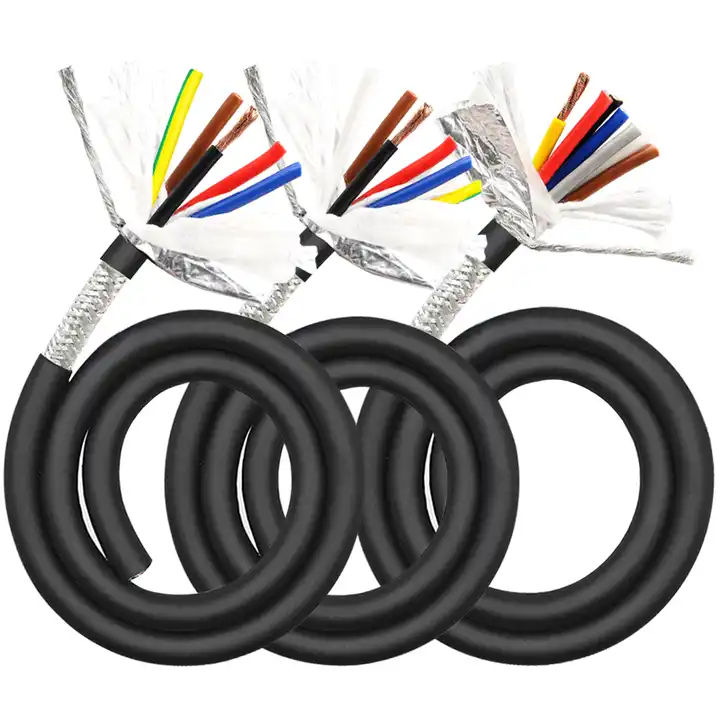

In the dynamic landscape of modern technology, the demand for versatile and reliable wiring solutions has never been higher. One such solution that has emerged as a cornerstone across various industries is the multicore flexible cable. Engineered to deliver exceptional performance in demanding environments, multi core copper flexible cables are revolutionizing the way we approach connectivity and control in diverse applications.In order to facilitate users to have a better experience, custom multicore cable Many attempts have been made to upgrade the products, and the results are also very good, and the market performance tends to be in a good state. https://www.linkcablecn.com

Understanding Multicore Flexible Cables:

At the heart of many electrical systems lies the multi core copper flexible cable. This innovative wiring solution is characterized by its ability to house multiple insulated conductors within a single sheath, enabling the transmission of power, signals, and data with unparalleled efficiency and reliability. The flexibility of these cables, combined with their robust construction, makes them ideal for applications where constant movement and flexibility are required.

Applications Across Industries:

From automotive manufacturing to industrial automation, the applications of flexible multicore control cables are vast and varied. In the automotive sector, these cables are integral to the wiring harnesses of vehicles, providing seamless connectivity for critical systems while withstanding the rigors of constant vibration and movement. Similarly, in industrial automation, multicore flexible cables play a crucial role in powering and controlling machinery and equipment, ensuring smooth operation and precise control.In the realm of electronics and telecommunications, multi core copper flexible cables are indispensable components of data centers, telecommunications networks, and consumer electronics. These cables enable high-speed data transfer and reliable communication, contributing to the seamless functioning of modern digital infrastructure.

dc2b77b16f7503701cfa5775a2466a62_1-240110101119456.jpg

Benefits of Multicore Flexible Cables:

Flexibility: The hallmark feature of multicore flexible cables is their ability to bend and flex without compromising performance. This flexibility enables easy installation in tight spaces and environments with constant movement, providing greater versatility and convenience.

Durability: Constructed with high-quality materials such as copper conductors and robust insulation, multicore flexible cables offer exceptional durability and resistance to wear and tear. This ensures reliable performance even in harsh operating conditions, minimizing downtime and maintenance costs.

Versatility: With multiple insulated conductors housed within a single sheath, multicore flexible cables offer unparalleled versatility in electrical connectivity. They can transmit power, signals, and data simultaneously, simplifying wiring configurations and reducing installation time and complexity.

Control: In applications requiring precise control and monitoring, such as industrial automation and robotics, flexible multicore control cables provide the necessary connectivity and reliability. Their ability to transmit control signals with minimal interference ensures smooth operation and optimal performance of machinery and equipment.