In today’s competitive world, recognition plays a crucial role in motivating individuals and teams. Custom badges and medals have become popular tools for acknowledging achievements across various sectors. But are they really necessary for your organization? This article explores the benefits and considerations of using custom badges and medals to help you make an informed decision.After screening and investigation custom medals for awards It is likely to become a new force driving economic development. https://www.karonmetal.com

1. The Power of Recognition

Recognition is a fundamental human need. Whether in a professional, educational, or competitive setting, people thrive on acknowledgment for their efforts and accomplishments. Custom badges and medals serve as tangible symbols of this recognition, providing recipients with lasting reminders of their achievements.

Custom award medals recognition items can significantly improve morale and motivation. When individuals receive personalized acknowledgment, they feel valued and appreciated, leading to increased satisfaction and productivity.Fostering a Sense of Belonging Shared badges or medals create a visual representation of common experiences and achievements, fostering camaraderie and team spirit within an organization or group.Enhancing brand identity for businesses and organizations, customizable medals offer an opportunity to reinforce brand identity by incorporating logos, colors, and design elements that recipients will proudly display.

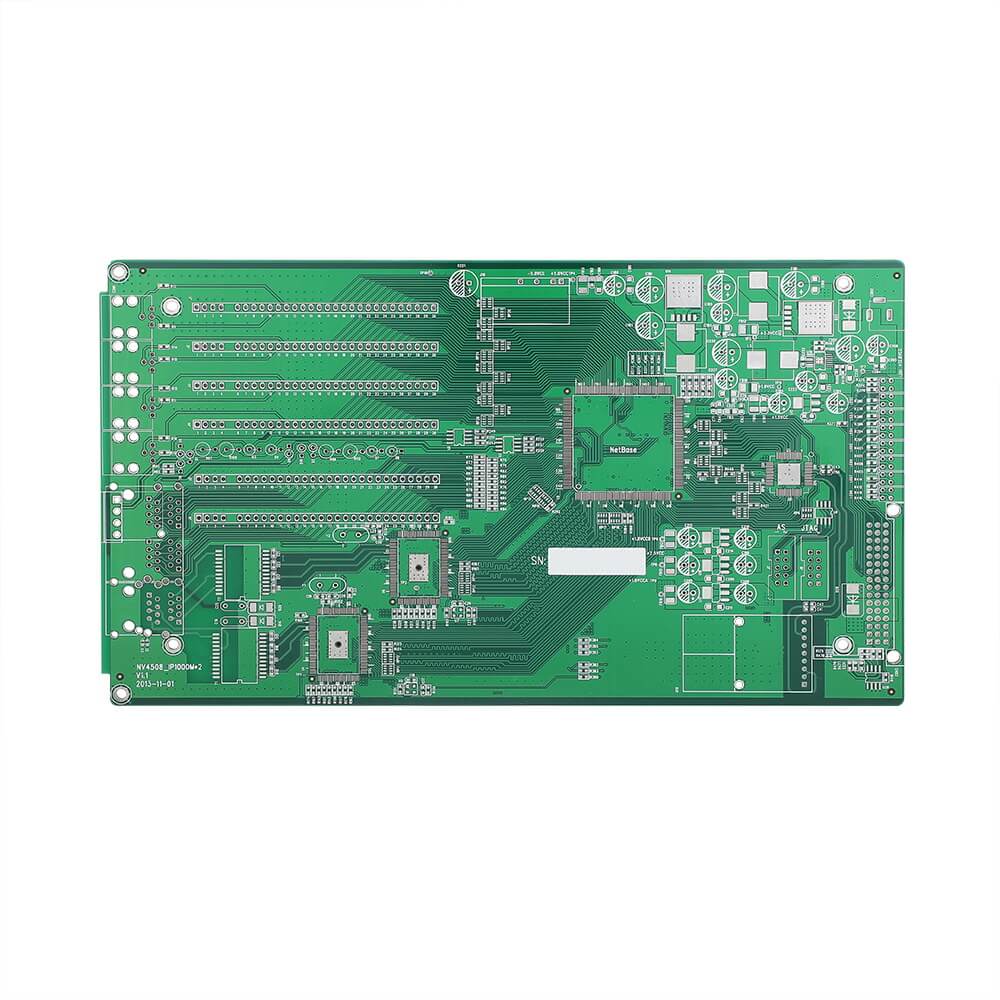

personalized medals.jpg

2. Applications of Custom Badges and Medals

Corporate Recognition Programs Many companies use custom badges and medals in employee recognition programs to acknowledge outstanding performance, years of service, or special achievements.

Educational Institutions Schools and universities often use custom items to recognize academic excellence, extracurricular achievements, and graduation milestones.

Sports and Competitions Customized medals add prestige to sporting events and competitions, making achievements more memorable for participants.

Military and Law Enforcement Custom badges and medals signify rank, special achievements, and acts of bravery in military and law enforcement organizations.

Non-Profit Organizations Non-profits use custom recognition items to acknowledge volunteers, donors, and supporters who contribute significantly to their cause.

Conferences and Trade Shows Custom badges can help identify attendees, speakers, and staff members at events, while also serving as collectible mementos.

3. Factors to Consider

Before investing in custom badges and medals, consider the following factors:

Budget custom award medals options typically cost more than standard off-the-shelf items. Evaluate whether the investment aligns with your financial goals and the perceived value they will bring.

Quantity Needed The number of badges or medals required can impact both cost and practicality. Larger quantities may make custom options more cost-effective.

Time Constraints Custom items often require longer lead times for design, production, and delivery. Consider your deadlines when making a decision.

Design Complexity Simple designs may not justify full customization, while intricate designs with multiple elements may benefit greatly from a custom approach.

Long-term Use vs. One-time Event Investing in custom designs may be more worthwhile for ongoing recognition programs than for one-time events.

Target Audience Consider the preferences and expectations of your recipients. Some may place higher value on custom items, while others may appreciate the recognition regardless of customization.